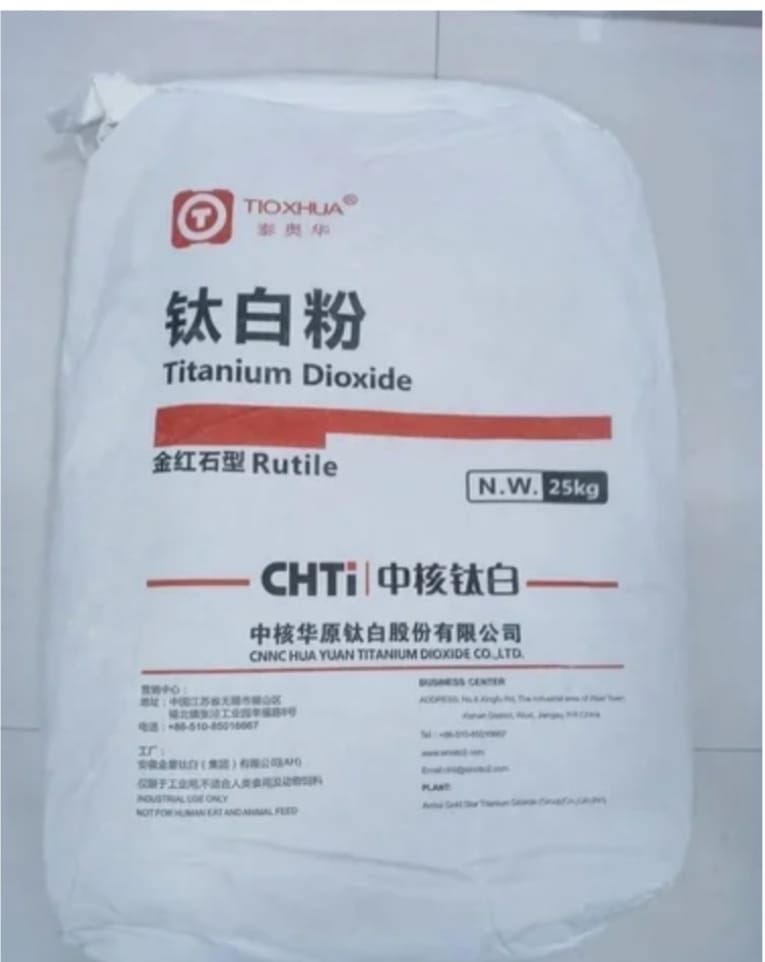

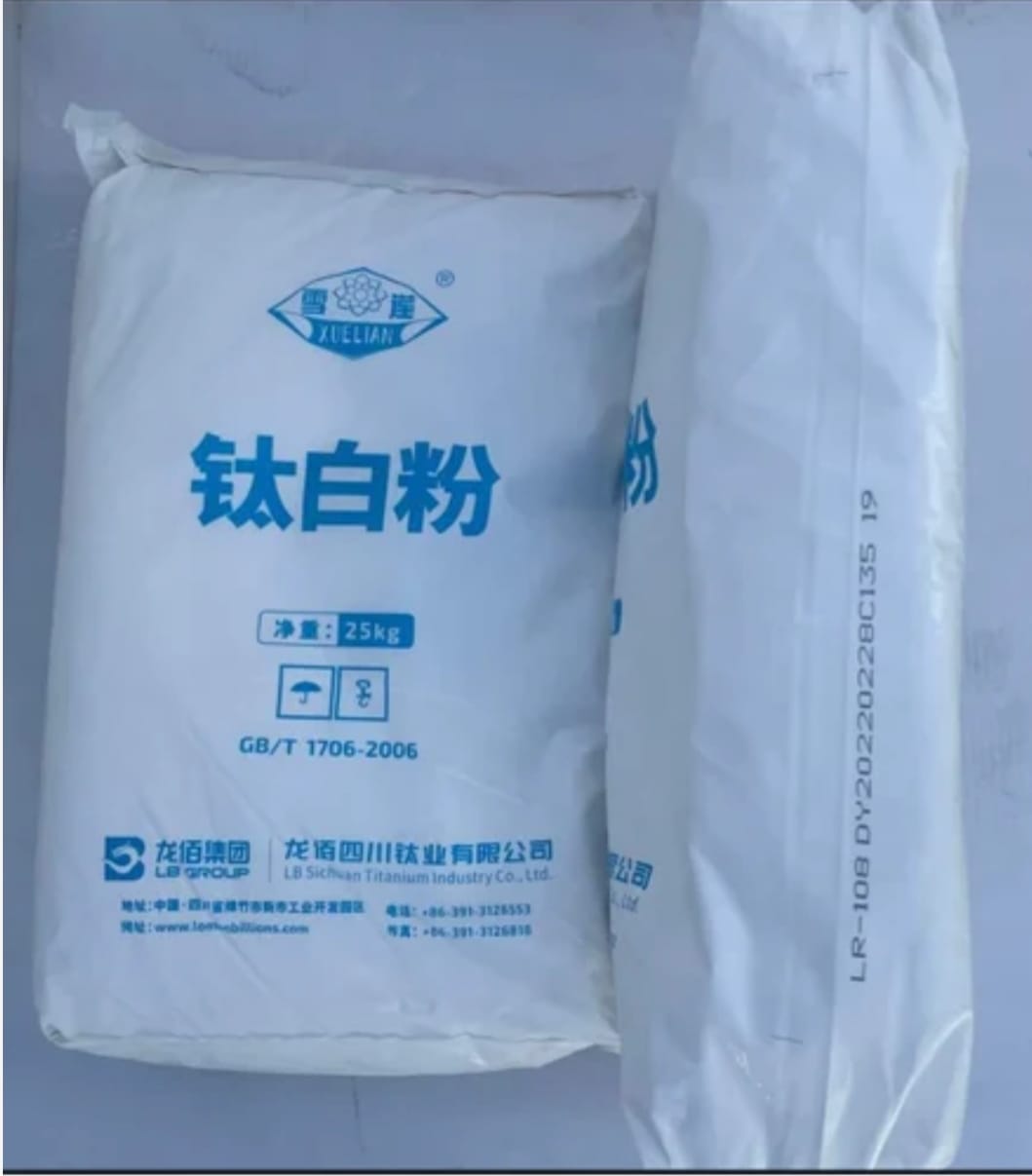

Titanium Dioxide Rutile all grade are available.

Titanium dioxide is widely used in coating, plastics, rubber, Ink, paper, chemical fiber, regenerated polyester, cosmetics, Ceramics, daily chemical, medicine, food and other industries. There are two kinds of titanium dioxide rutile and titanium Dioxide anatase. The most important applications for Titanium dioxide is for its use in the manufacture of paints And varnishes as well as paper and plastics, which account for About 80% of the world’s consumption. Jinan Ogilvy chemical Provides high-quality titanium dioxide, and can be used in conjunction With optical brightener to customized products brightening program.

High Opacity and Brightness

Titanium Dioxide Rutile is known for its superior whiteness and ability to provide excellent coverage, making it ideal for paints, coatings, and plastics.

UV and Weather Resistance

Its high refractive index and UV-blocking capabilities make it perfect for outdoor applications that require durability and protection from sunlight.

Versatile Industrial Applications

Widely used across various industries, including paints, plastics, cosmetics, paper, and inks, due to its excellent pigment and stability properties.

Used In Following Industries

- Ink

- Paint

- Rexine

- Leather

- Power Coating

- Plastic

- Masterbatches

- Raod Marking Paint

- Cosmetic

Titanium Dioxide Rutile is a white pigment known for its excellent brightness, high refractive index, and UV resistance. It is widely used in paints, coatings, plastics, paper, cosmetics, and even food products as a whitening and opacifying agent.

Yes, when produced to the appropriate standards and within regulated limits, Titanium Dioxide Rutile is considered safe for use in cosmetics and food. However, safety depends on particle size and purity, so it's essential to ensure it meets FDA or relevant regulatory guidelines.

It should be stored in a cool, dry place, away from moisture and direct sunlight. The packaging should be sealed properly to prevent contamination or clumping, which can affect its performance in formulations.